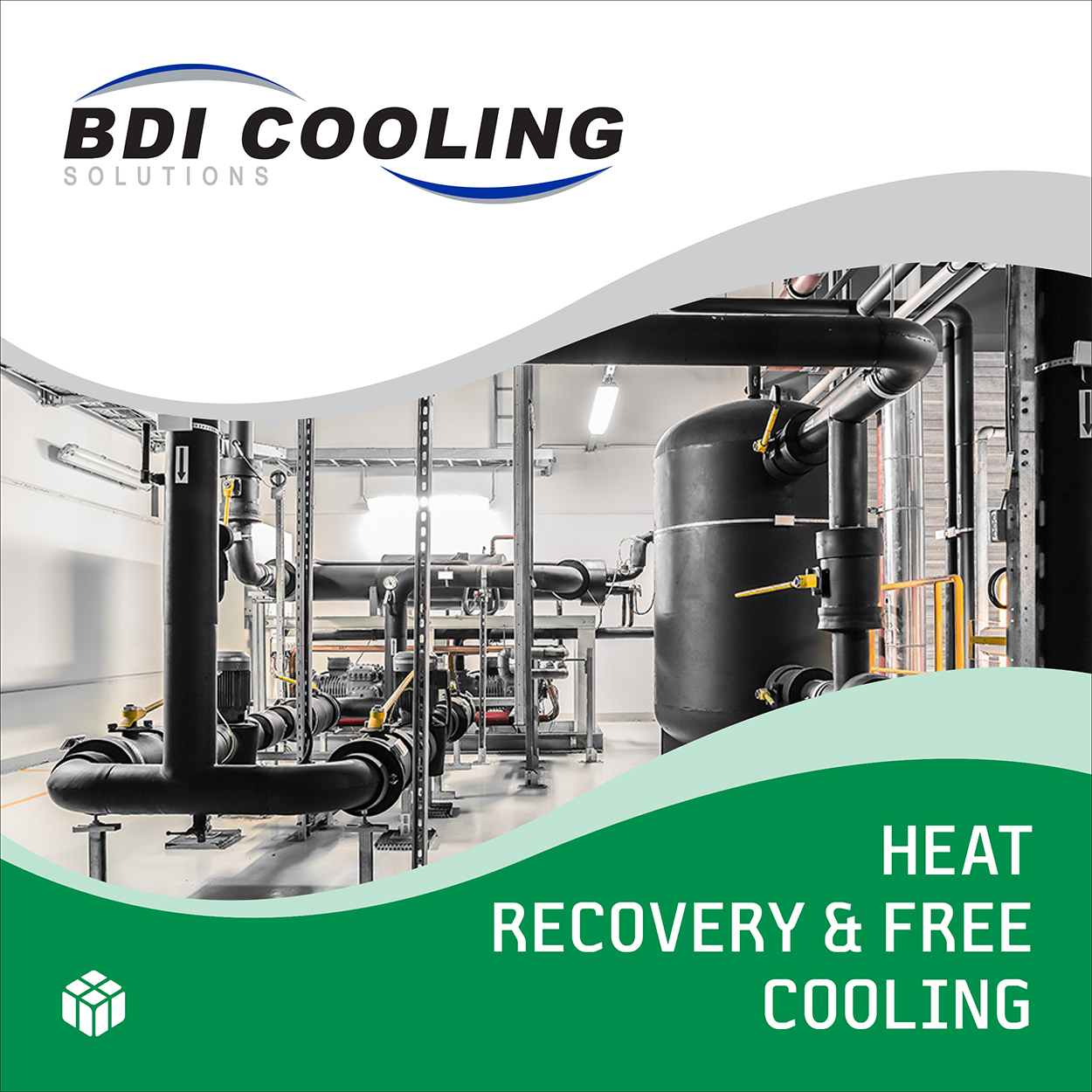

Heat Recovery Systems

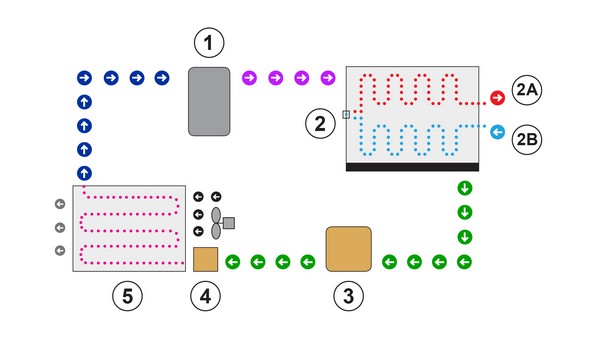

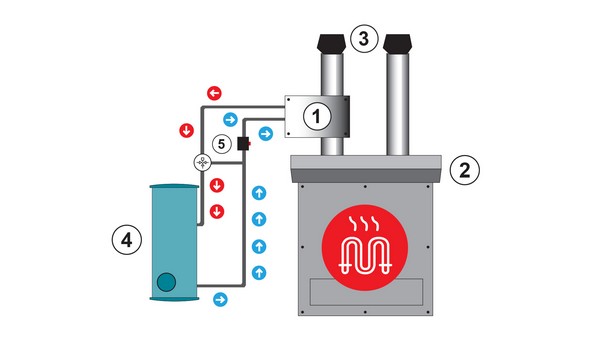

Heat recovery is the collection and re-use of heat arising from a process that would otherwise be lost or ‘wasted’. To reclaim this wasted energy there needs to be a lower temperature ‘heat sink’ where the wasted energy can be effectively / economically used.

- Boilers that provide heat for any process

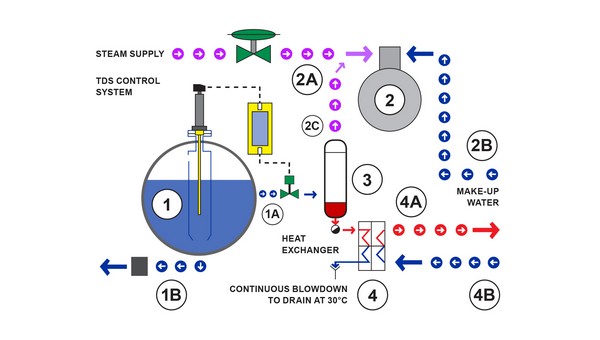

- Steam boiler blowdown

- Flash steam

- Steam de-superheaters

- Heat rejection from process cooling systems

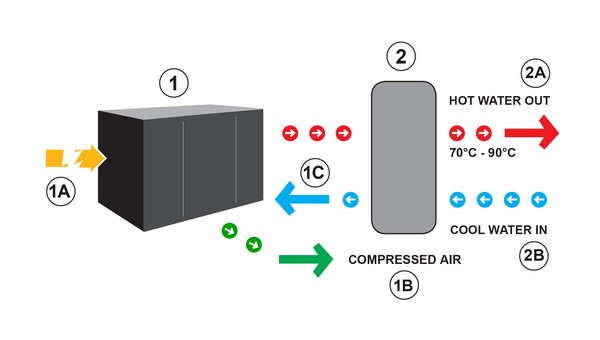

- Air compressors

- Hot exhaust air

- Heat stored in products leaving the process

- Heat in gaseous and liquid effluents leaving the process

- Heat in cooling hydraulic oil systems.

Recovered heat is a valuable and flexible resource. The following is a list of the most common uses for recovered heat:

- Heating of steam system make-up water

- Heating of wash down water

- Paint facilities / wash lines

- Space heating / central heating

- Domestic hot water i.e. toilets, kitchens, laboratories, showers etc

- Boiler return water heating

- Process heating

- Combustion air pre-heating

- Electrical generation (organic rankine cycle, steam turbine or expanders)

- Absorption chillers

- Drying.

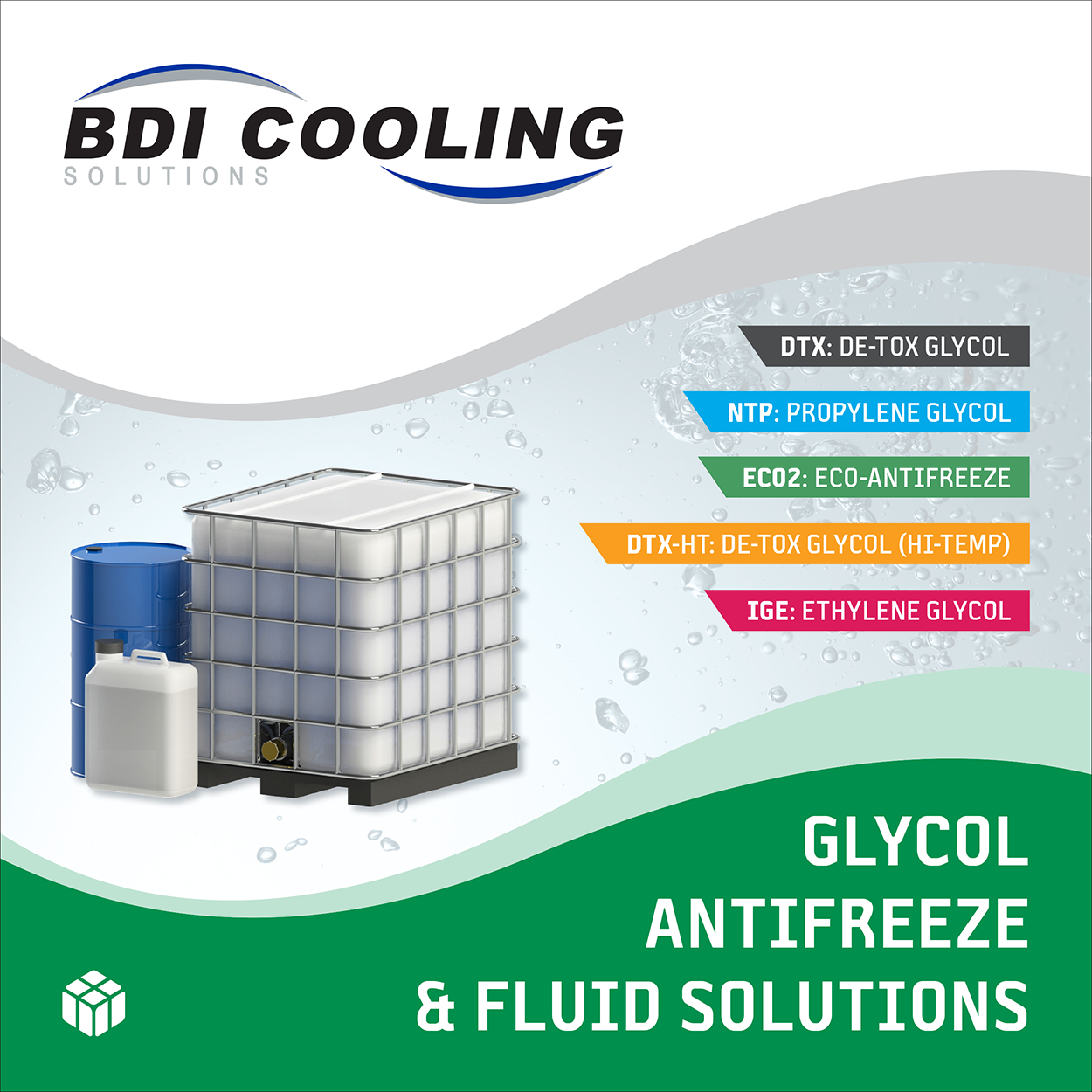

BDIC strive to ensure end users and distributors receive the full benefit of working with a specialist supplier that offers:

- Expert Technical advice on all aspects of fluid selection, including Environmental Impact Assessments, Thermal Performance etc

- Fluid Maintenance Programs for the proactive verification of fluid and system condition

- A vast stock inventory facilitating same day dispatch and delivery

- Bespoke formulations for specialist applications.

For further information about these systems please email: info@bdicooling.com

BIJUR DELIMON INTERNATIONAL

RAMSDEN COURT, RAMSDEN ROAD

ROTHERWAS INDUSTRIAL ESTATE

HEREFORD HR2 6LR

T: +44 (0) 1432 365000

E: info@bdicooling.com

W: www.bdicooling.com

WENTA BUSINESS CENTRE

1 ELECTRIC AVENUE, INNOVA SCIENCE PARK

ENFIELD, LONDON EN3 7XU

T: +44 (0) 1432 262107

OFFICE 12, SOUTHLANDS BUSINESS CENTRE

ORMESBY ROAD, MIDDLESBROUGH

TS3 0HG

T: +44 (0) 1432 365000

UNIT 47, ENDEAVOUR CLOSE

PURCELL AVENUE INDUSTRIAL ESTATE

PORT TALBOT SA12 7PT

T: +44 (0) 1639 891885