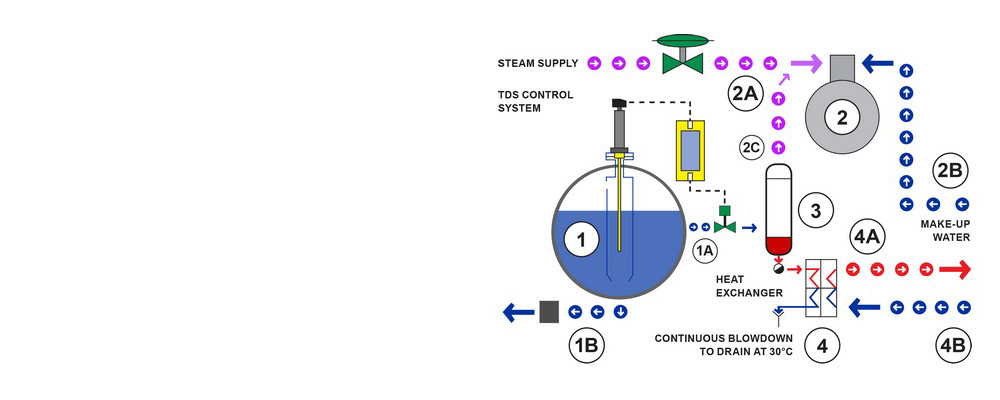

Steam Plant Heat Recovery

Steam systems offer multiple opportunities for energy recovery, the most common being flash energy recovery and TDS blowdown energy recovery. Routinely and in some cases constant TDS sampling operations on steam systems allow for energy recovery from flash steam and also the condensate to drain. The energy can be recovered via a heat exchanger and/or flash vessel depending on the application. Other flash steam recovery (from blowdown vessel, condensate receivers, etc) can further improve system efficiencies by recovering the energy and potentially returning condensed steam to the condensate system to reduce water make-up and chemical treatment. Steam de-superheaters also offer energy recovery opportunities.

- Recovery of otherwise lost energy

- Simple system and installation

- Retrofittable

- Improved boiler efficiency

- Reduced running costs

- Attractive return on investment periods.

The range of uses for this heat will depend on the application and temperatures of the system, however typically could be used for:

- Heating of steam system make-up water

- Heating of wash down water

- Paint facilities / wash lines

- Space heating / central heating

- Domestic hot water i.e. toilets, kitchens, laboratories, showers etc

- Boiler return water heating

- Process heating

- Combustion air pre-heating

- Electrical generation (organic rankine cycle, steam turbine or expanders)

- Absorption chillers

- Drying.

BDIC strive to ensure end users and distributors receive the full benefit of working with a specialist supplier that offers:

- Expert Technical advice on all aspects of fluid selection, including Environmental Impact Assessments, Thermal Performance etc

- Fluid Maintenance Programs for the proactive verification of fluid and system condition

- A vast stock inventory facilitating same day dispatch and delivery

- Bespoke formulations for specialist applications.

For further information about these systems please email: info@bdicooling.com

BIJUR DELIMON INTERNATIONAL

RAMSDEN COURT, RAMSDEN ROAD

ROTHERWAS INDUSTRIAL ESTATE

HEREFORD HR2 6LR

T: +44 (0) 1432 365000

E: info@bdicooling.com

W: www.bdicooling.com

WENTA BUSINESS CENTRE

1 ELECTRIC AVENUE, INNOVA SCIENCE PARK

ENFIELD, LONDON EN3 7XU

T: +44 (0) 1432 262107

OFFICE 12, SOUTHLANDS BUSINESS CENTRE

ORMESBY ROAD, MIDDLESBROUGH

TS3 0HG

T: +44 (0) 1432 365000

UNIT 47, ENDEAVOUR CLOSE

PURCELL AVENUE INDUSTRIAL ESTATE

PORT TALBOT SA12 7PT

T: +44 (0) 1639 891885