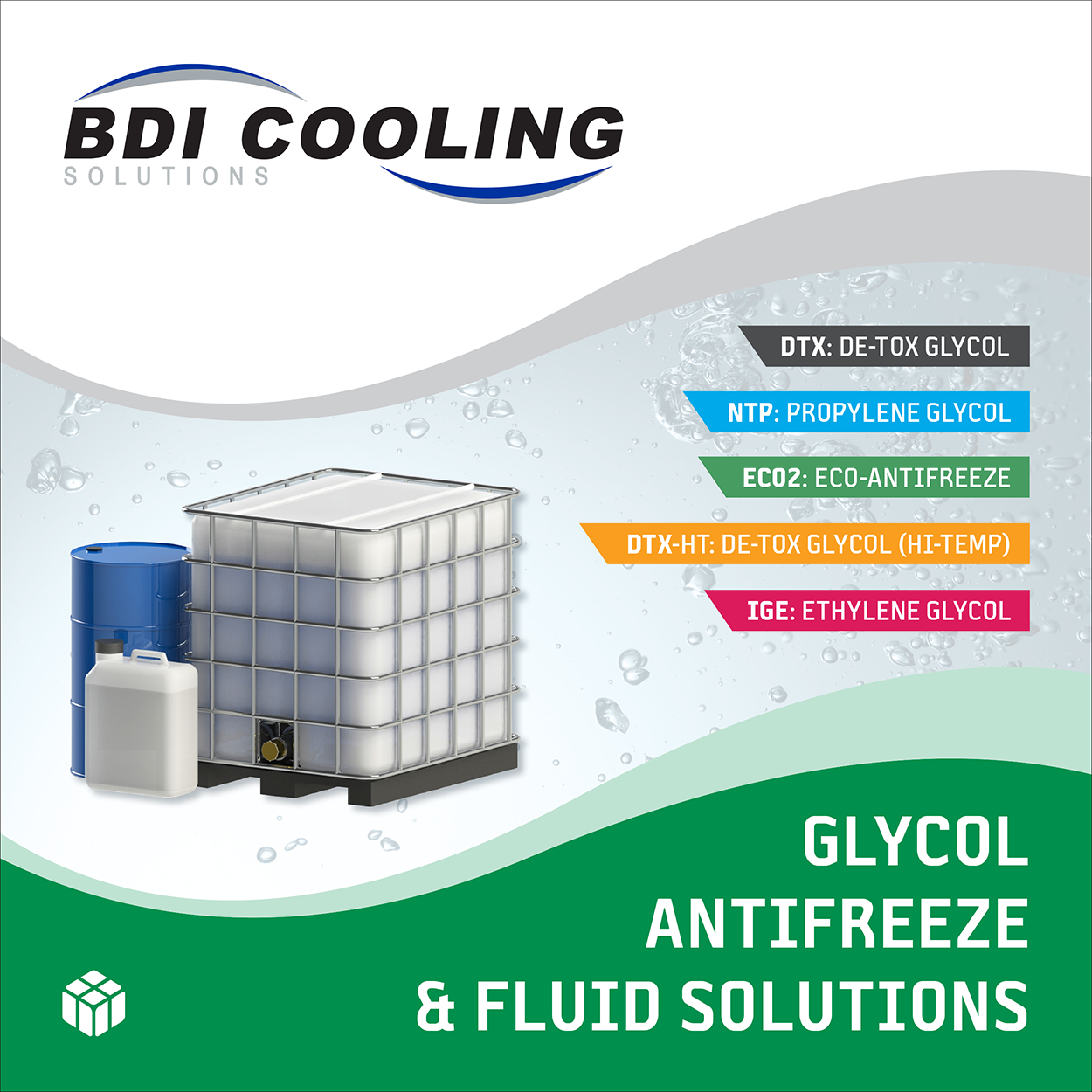

IGE: Ethylene Glycol Antifreeze

Industrial grade secondary refrigerant Antifreeze for Process Cooling & AC systems. Based on Ethylene Glycol and ASTM D1384 proven corrosion, scale and biological inhibitors.

IGE: Ethylene Glycol Antifreeze has been especially formulated from Ethylene Glycol for use as a industrial grade secondary refrigerant Antifreeze for use in Process Cooling, Refrigeration and Air Conditioning systems, where toxicity is not an issue.

IGE: Ethylene Glycol Antifreeze is miscible with water in all proportions and can protect RAC systems down to -50 °C depending on concentration. IGE: Ethylene Glycol Antifreeze exhibits super-cooling characteristics and mixtures containing in excess of 55% by volume do not freeze solid, alleviating any concern over possible expansion and burst damage.

IGE: Ethylene Glycol Antifreeze has improved heat transfer characteristics including lower dynamic viscosity and higher thermal conductivity. For a detailed comparison please refer to the Fluid Performance Chart which is available upon request.

IGE: Ethylene Glycol Anti freeze contains synergistic corrosion inhibitors to protect metals commonly found in such systems. It has been tested in accordance with BS5117 and found to meet BS6580 and ASTM D1384 corrosion standards. IGE: Ethylene Glycol Antifreeze also contains scale and biological inhibitors to help prevent fouling - thus promoting long operational life and high thermal efficiency.

IGE: Ethylene Glycol Antifreeze mixtures are readily biodegradable (90% over 10 days) and will not remain in the environment or bio-accumulate.

All BDIC Glycol products are manufactured in accordance with certified ISO 9001-2008 procedures.

IGE: Ethylene Glycol Antifreeze is a clear, slightly viscous liquid and mildly sweet to the taste. It is non-pungent however it does have a characteristic aroma.

| Density: | 1.08 - 1.2 g/cm3 depending on inhibitors |

| pH: | 7.5 - 10.5 depending on inhibitors |

| Boiling Point: | >100 °C |

As per BSRIA guide BG 29/2012 all pipework systems should be clean and free from biological contamination and debris prior to commissioning. To minimse corrosion, air ingress should be minimised. A pressurised system is best.

Determine the total system volume and add IGE: Ethylene Glycol Antifreeze to the system according to the minimum operating temperature required (see table below).

The minimum dose of IGE: Ethylene Glycol Antifreeze should not be less than 25% of the system volume and the maximum does not normally exceed 60%. We recommend the use of deionised, distilled or UltraPure™ water for this dilution. Avoid water containing high levels of calcium salts or chlorides [CI-].

When measuring the percentage concentration of IGE: Ethylene Glycol Antifreeze in solution we recommend the use of a recently calibrated refractometer.

Please refer to the associated product Safety Data Sheet which is available upon request.

3 years when stored in sealed containers out of direct sunlight.

25, 205 & 1000 Litre IBC’s and bulk tankers.

IGE: Ethylene Glycol Antifreeze can also be supplied as a ready-to-use solution.

| Frost Protection °C | V/V of IGE: Ethylene Glycol | Refractive Index |

|---|---|---|

| -10 | 20% | 1.349 |

| -15 | 27% | 1.355 |

| -20 | 32% | 1.359 |

| -25 | 37% | 1.363 |

| -30 | 41% | 1.366 |

| -35 | 45% | 1.369 |

BDIC strive to ensure end users and distributors receive the full benefit of working with a specialist supplier that offers:

- Expert Technical advice on all aspects of fluid selection, including Environmental Impact Assessments, Thermal Performance etc

- Fluid Maintenance Programs for the proactive verification of fluid and system condition

- A vast stock inventory facilitating same day dispatch and delivery

- Bespoke formulations for specialist applications.

For further information about this product please email: info@bdicooling.com

BIJUR DELIMON INTERNATIONAL

RAMSDEN COURT, RAMSDEN ROAD

ROTHERWAS INDUSTRIAL ESTATE

HEREFORD HR2 6LR

T: +44 (0) 1432 365000

E: info@bdicooling.com

W: www.bdicooling.com

WENTA BUSINESS CENTRE

1 ELECTRIC AVENUE, INNOVA SCIENCE PARK

ENFIELD, LONDON EN3 7XU

T: +44 (0) 1432 262107

OFFICE 12, SOUTHLANDS BUSINESS CENTRE

ORMESBY ROAD, MIDDLESBROUGH

TS3 0HG

T: +44 (0) 1432 365000

UNIT 47, ENDEAVOUR CLOSE

PURCELL AVENUE INDUSTRIAL ESTATE

PORT TALBOT SA12 7PT

T: +44 (0) 1639 891885